Food network

- Voltage: 220 VAC, 50 Hz

- Power consumption: 2-5 kW

- Voltage fluctuations: 170 - 260 V

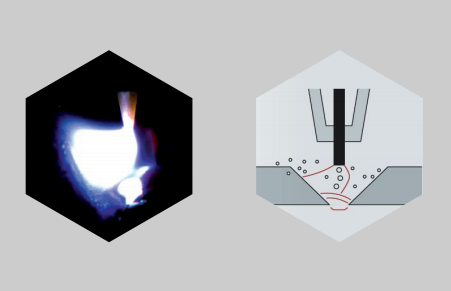

Welding of pipes while performing the repair and restoration works on main pipelines is carried out by manual arc welding using basic-coated electrodes. At that, root welding using direct current is often accompanied by the effect of magnetic blow showing itself in arc blowout and deflection at pipe joints due to their high residual magnetization.

Pipe magnetization occurs due to the use of magnetic pipeline pigs to assess the wall thickness and identify metal defects in high-pressure gas pipelines. The magnetic field at the pipe joints can come up to 100-150 mT (1000-1500 G) and even more. A high magnetic field leads to unstable arcing, spattering, formation of welding defects, such as pores, lack of penetration, and slag inclusions.

The level of residual magnetization of pipe ends of no more than 2 mT (20 G) is established by a number of standards. When magnetization is more than 2 mT, demagnetization should be performed. However, the practice of welding on main pipelines showed that the magnetization value at the pipe joints of the order of 10 G (1.0 mT) already causes arc deflection and welding process failure.

The acceptable pipe magnetization values for MMA welding:

Welding defects caused by high magnetization of pipes lead to loss of time for dressing, re-welding and additional inspection during repair work on main gas and oil pipelines. Since the residual magnetization of pipes does not allow to obtain good weld quality, demagnetization of pipes prior to welding is a necessary procedure. It is not possible to completely eliminate the magnetic field, therefore it is allowed to weld at low values of pipe magnetization not having a negative impact on the quality of welding.

THE CHALLENGES OF MAGNETIZED PIPES WELDING:

NEVA-Tekhnika manufactures pipe demagnetizers to ensure high quality welded joints of main pipelines when working under harsh field conditions.

NEVA series demagnetizers are used to demagnetize pipes when performing repair work on pipelines with a diameter of up to 1420 mm.

We produce several variants of units and devices for pipe demagnetization:

We also provide pipe demagnetizers for rent and render services for demagnetization of main pipelines at customer’s site throughout Kazakhstan.

MD-T1.P3

THE APPLICATION OF INTERNAL PIPELINE PIGS FOR ASSESSMENT OF THE CONDITION OF HIGH PRESSURE GAS PIPELINES RESULTS IN AN INCREASE IN THE RESIDUAL PIPE MAGNETIZATION

Pipe magnetization causes unstable arcing and arc break. At that, such welding defects as pores, lack of fusion, lack of penetration, as well as slag inclusions are formed

Pipe demagnetization results in normalization of arcing at joints, thus ensuring high-quality seam welding